In-house Production

- Experience & Tradition in manufacturing over 42 years

- 420+ high qualify employees

- Production zone on over 16000+ meter square

- Experience & Tradition in manufacturing over 42 years

- 420+ high qualify employees

- Production zone on over 16000+ meter square

We use highly optimized equipment from WindoorTester which is in accordance with the current industry norms. WindoorTester enables constant supervision over the production process. Maintaining the quality of manufactured products is achieved through the possibility of frequent checks of the finished products.

All our employees regularly attend internal and external seminars, so as to be able to keep track of the challenges on the market. In addition to a highly qualified and motivated workforce, one of the indicators of the quality of our products is the fact that we use only the highest quality raw materials. PVC is produced from the best known German profiles by systems TROCAL and KÖMMERLING. ALU products are made of profiles according to the FEAL, SCHÜCO, and ALIPLAST systems.

Staff

- 412573 QM9001 2015 Quality Management System (ISO 9001:2015)

- 412573 UM14001 2015 Environmental Management System (ISO 14001:2015)

- 412573 OHS45001 2018 Occupational Health and Safety Management System (ISO 45001:2018)

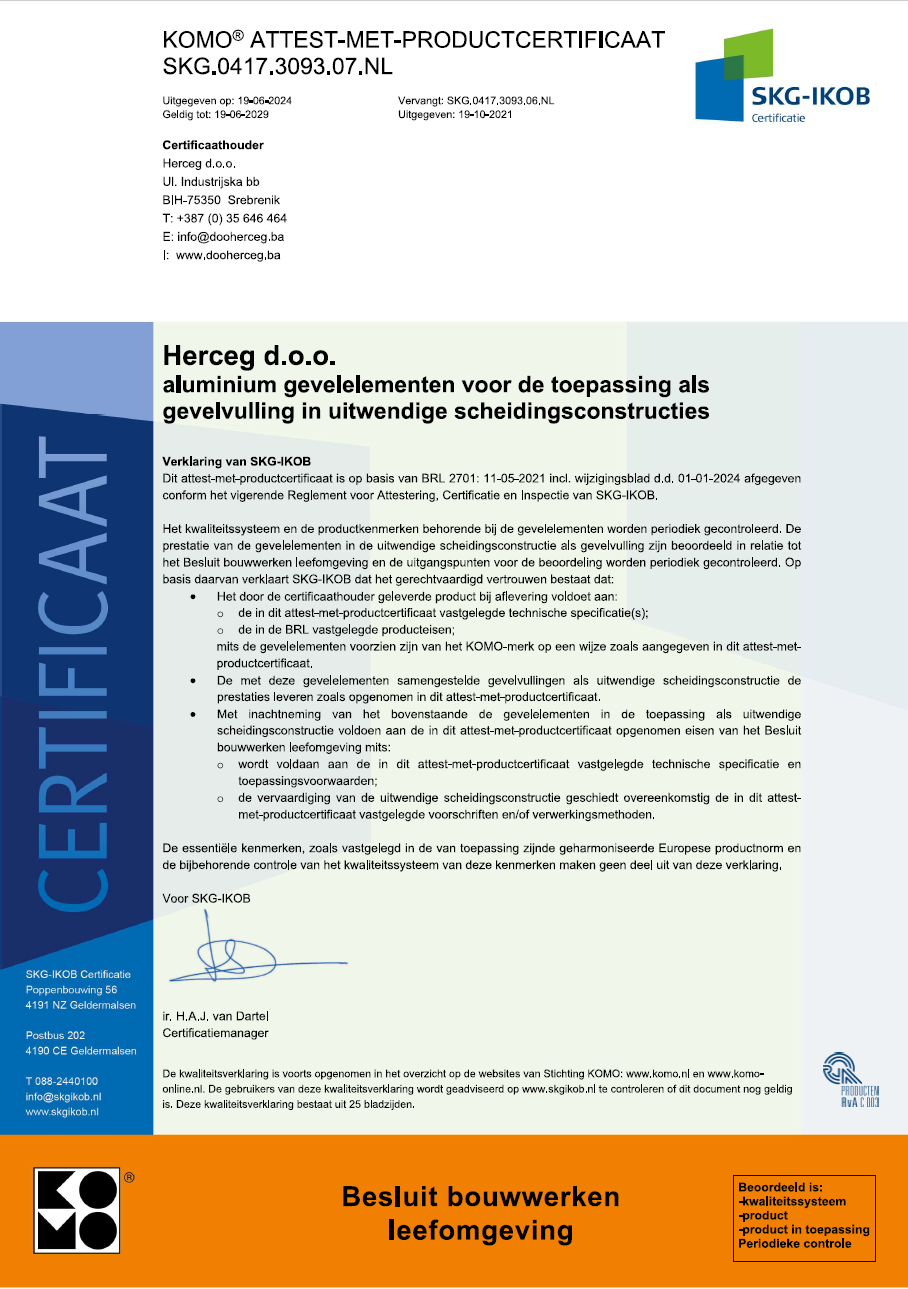

- SKG.0417.3093.07 production, processing, performance, transport, installation, maintenance of aluminum products

- SKG.0417.0037.07.NL products from the PVC Profine K Vision system with HVL joint

- SKGIKOB.011622.03.NL anti-burglary properties of products in the PVC system Profine K-VISION 76 mm/120 mm

- SKGIKOB.011623.04.NL components, performance, and installation of PVC products from Profine K-VISION 76/120 mm

- SKGIKOB.011625.03.NL anti-burglary properties of 2-, 3-, and 4-wing sliding positions made of plastic from the PremiDoor 76 & PremiDoor 76Lux system

- 0960-CPR-SKGIKOB.012659.01 production of pedestrian doors on emergency routes (panic doors)

- C-Coat_QCT Mgmt_QUALICOAT_Certificate 2025 - Lic 5106